1000Mtr / gulungan SS316L Stainless Steel Coiled Tubing

Pelanggan sing dihormati, aku seneng ngenalake sampeyan premium stainless steel 316L Kelas Seamless Coiled Tubing.We are Produsèn tubing coiled profesional karo produksi kelas kapisan lan peralatan testing.Kita bisa gawé 316L coiled tubing saka macem-macem specifications, OD kalebu 3/4in, 1in, 1 1/2in, 1 3/4in, 2in, 2 3/8in, etc. Specifications bisa selaras.Produk kita tundhuk karo ASTM A269, ASTM A789, ASTM B704, ASTM A370, ASTM A450, ASTM E426 lan standar liyane.Sajrone pirang-pirang taun, kita wis gabung karo proyek karo KNPC, KOC lan perusahaan minyak nasional lan produk kita wis adol kanthi apik ing saindenging jagad.Kualitas produk wis dipuji dening para pelanggan.Kita bisa ngasilake seamless lan gandheng coiled tubing.Sawetara gulungan pipa sing digulung dawane 100-30,000 ft lan digunakake ing Sumur jero banyu.Yen perlu, welcome kanggo takon, katon nerusake kanggo nggarap sampeyan!

SIFAT FISIK

Kekuwatan ngasilake: ≥40.000 psi

Kekuwatan tarik: ≥70.000 psi

Atose maksimum: 200HV

KOMPOSISI KIMIA-%

Karbon ≤0,030

Mangan ≤2.00

Fosfor ≤0,045

Sulfur ≤0,030

Silikon ≤0.75

Kromium 16.0-18.0

Nikel 10.0-14.0

Molybdenum 2.00-3.00

Beban awak tabung:

Ngasilake & Tensile Minimum diwilang ing Tembok Ditemtokake.

Tekanan Uji Hidrostatik:

Kabeh senar pipa coiled sing wis rampung kudu diuji tekanan hidrostatik sadurunge dikirim. Tekanan uji hidrostatik kudu kurang saka 90% saka kekuatan ngasilake bledosan teoritis utawa 17,500 psi utawa 120700 kpa (kajaba disepakati khusus antarane panuku lan pabrikan).

Hasil Internal: Tekanan Internal kanggo

nyebabake ngasilake nggunakake Minimum Yield

Kekuwatan lan Kekandelan Tembok Minimal.

Tekanan Kerja Maksimum minangka fungsi saka kondisi tabung lan ditemtokake dening pangguna.

Nilai Torsi Diwilang Nggunakake Kekandelan Tembok Minimal lan Kekuwatan Ngasilake Minimal.

Ukuran liyane / kekandelan tembok kasedhiya ing panyuwunan.

Data ing ndhuwur kanggo pipa anyar kanthi kekuwatan minimal sing ditemtokake.

Tabel komposisi kimia saka bahan stainless steel

| KELAS A312 | UNS | C | Mn | P | S | Si | Cr | Ni | Mo | Ti | Nb | N |

| TP304 | S30400 | 0.08 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 8.0-11.0 | ||||

| TP304L | S30403 | 0.035 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 8.0-13.0 | ||||

| TP304H | S30409 | 0.04-0.10 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 8.0-11.0 | ||||

| TP304N | S30451 | 0.08 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 8.0-18.0 | 0.10-0.16 | |||

| TP304LN | S30453 | 0.035 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 8.0-12.0 | 0.10-0.16 | |||

| TP309S | S30908 | 0.08 | 2 | 0.045 | 0.03 | 1 | 22.0-24.0 | 12.0-15.0 | 0.75 | |||

| TP309H | S30909 | 0.04-0.10 | 2 | 0.045 | 0.03 | 1 | 22.0-24.0 | 12.0-15.0 | ||||

| TP309Cb | S30940 | 0.08 | 2 | 0.045 | 0.03 | 1 | 22.0-24.0 | 12.0-16.0 | 0.75 | 10xC min | ||

| 1.10 maks | ||||||||||||

| TP309HCb | S30941 | 0.04-0.10 | 2 | 0.045 | 0.03 | 1 | 22.0-24.0 | 12.0-16.0 | 0.75 | 10xC min | ||

| 1.10 maks | ||||||||||||

| TP310S | S3108 | 0.08 | 2 | 0.045 | 0.03 | 1 | 24.0-26.0 | 19.0-22.0 | 0.75 | |||

| TP310H | S3109 | 0.04-0.10 | 2 | 0.045 | 0.03 | 1 | 24.0-26.0 | 19.0-22.0 | ||||

| TP310Cb | S31040 | 0.08 | 2 | 0.045 | 0.03 | 1 | 24.0-26.0 | 19.0-22.0 | 0.75 | 10xC min | ||

| 1.10 maks | ||||||||||||

| TP310HCb Kab | S31041 | 0.04-0.10 | 2 | 0.045 | 0.03 | 1 | 24.0-26.0 | 19.0-22.0 | 0.75 | 10xC min | ||

| 1.10 maks | ||||||||||||

| TP316 | S3160 | 0.08 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 11.0-14.0 | 2.0-3.0 | |||

| TP316L | S31603 | 0.035 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | |||

| TP316H | S31609 | 0.04-0.10 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 11.0-14.0 | 2.0-3.0 | |||

| TP316Ti | S31635 | 0.08 | 2 | 0.045 | 0.03 | 0.75 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | 5x | 0.1 | |

| (CN) | ||||||||||||

| -0.7 | ||||||||||||

| TP316N | S31651 | 0.08 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | 0.10-0.16 | ||

| TP316LN | S31653 | 0.035 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 11.0-14.0 | 2.0-3.0 | 0.10-0.16 | ||

| TP317 | S3170 | 0.08 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 10.0-14.0 | 3.0-4.0 | |||

| TP317L | S31703 | 0.035 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 11.0-15.0 | 3.0-4.0 | |||

| TP321 | S3210 | 0.08 | 2 | 0.045 | 0.03 | 1 | 17.0-19.0 | 9.0-12.0 | 0.1 | |||

| TP321H | S32109 | 0.04-0.10 | 2 | 0.045 | 0.03 | 1 | 17.0-19.0 | 9.0-12.0 | 0.1 | |||

| TP347 | S3470 | 0.08 | 2 | 0.045 | 0.03 | 1 | 17.0-19.0 | 9.0-13.0 | ||||

| TP347H | S34709 | 0.04-0.10 | 2 | 0.045 | 0.03 | 1 | 17.0-19.0 | 9.0-13.0 | ||||

| TP347LN | S34751 | 0.05-0.02 | 2 | 0.045 | 0.03 | 1 | 17.0-19.0 | 9.0-13.0 | 0.20- | 0.06-0.10 | ||

| 50 | ||||||||||||

| TP348 | S3480 | 0.08 | 2 | 0.045 | 0.03 | 1 | 17.0-19.0 | 9.0-13.0 | ||||

| TP348H | S34809 | 0.04-0.10 | 2 | 0.045 | 0.03 | 1 | 17.0-19.0 | 9.0-13.0 | ||||

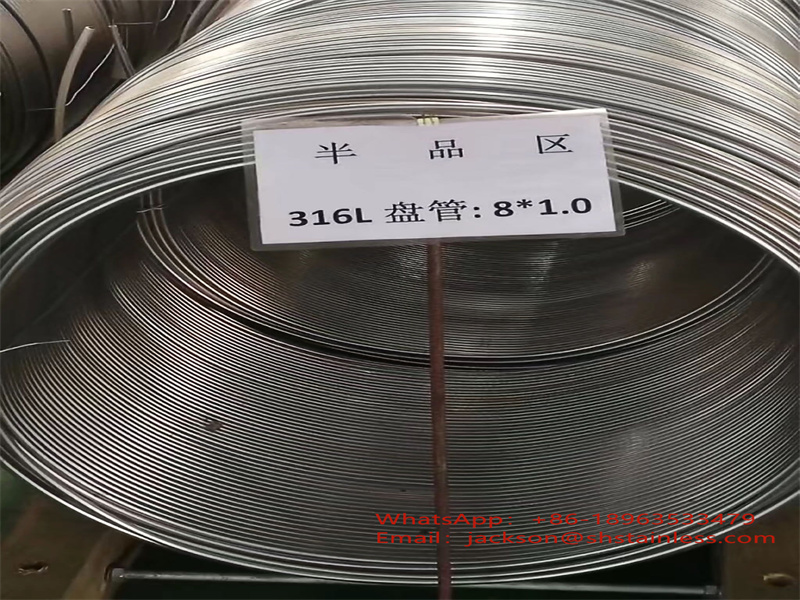

Pipa coiled & pipa coiled

Jeneng produk: Stainless Steel Coiled tubing lan Coiled line pipe

Jinis lan spesifikasi produk:

OD: 19.05mm ~ 88.9mm

WT: 1.91mm-7.62mm

Dawane: Maks.8000m

Bobot maksimal gulungan tunggal: 30t (ora kalebu rol)

Dhiameter njaba maksimal drum: 3,40m

Spesifikasi: ASTM A269, A213, ASTM A789, ASTM B704, ASTM A370, ASTM A450, APIRP5 C7, JISG4305, JIS G3463, DIN2469, Spesifikasi API 5ST, Spesifikasi API.5 LCP

Kelas baja: Spesifikasi API.5ST CT70-CT110, Spesifikasi API.5LCP X52C~X90C,

316L, 304L, Inconel625, Incoloy825, UNS N04400, UNS S32205/S31803(ASTM A240), S2507/UNS S32750

Kekuwatan ngasilake: coiled tubing 483mpa-758mpa (70ksi-110ksi), coiled line pipe 359mpa-621mpa (52ksi-90ksi)

Cathetan: spesifikasi khusus, bahan lan dawa produk bisa disesuaikan miturut syarat pelanggan

We duwe pengalaman ekstensif ing prodhuksi coiled tubing saka duplex, alloy nikel lan gelar stainless steel kanggo industri lan customer-tartamtu syarat.Coiled tubing kasedhiya ing dawa saka 100 kaki (30 meter) kanggo 30.000 kaki (10.000 meter). Tubing bisa coiled dhateng IPPC-certified kayu utawa logam reels selaras kanggo specifications kedhaftar.Aplikasi kalebu pipa kapiler kanggo injeksi kimia, garis kontrol hidraulik sing gundhul lan enkapsulasi kanggo katup safety subsea, senar kecepatan, senar kerja, lan umbilicals tabung baja.

EMHK ngasilake tabung koil medis baja tahan karat sing dipoles lan pipa baja tahan karat Metrik.Bisa digunakake ing Platform Pengeboran Minyak, Sumur Minyak, Heatwell. Iki nyedhiyakake salah sawijining kisaran kualitas paling apik saka pipa kumparan medis stainless steel sing dipoles lan pipa baja tahan karat metrik.Tabung coil medis digawe saka macem-macem bahan.Pipa kumparan medis stainless steel sing dipoles yaiku tabung baja tahan karat sing dipoles sing digunakake kanggo nggawe gulungan ing peralatan medis.

316LSeamless stainless steel coiled tube/pipe,Material: 304 / 304L / 316 / 316L / Duplex 2205 / Monel 400 / Inconel 625 / Inconel 825 ,Permukaan: Ing njero lan njaba padhang anil, resik lan tanpa proses leakage. ukuran: 1/8 "* 0,025", 1/4" * 0,049 ", 3/8" * 0,049 ", 1/2" * 0,049 ", 1/2" * 0,065 ", 3/4" * 0,075″ 1″*0.075,1 1/2″*0.083″,2″*0.109″,2 3/8*0.109″,2 5/8*0.118″,3 1/2*0.156″, lsp.

Ukuran pipa kapiler stainless steel lan Peringkat Tekanan:

| Ukuran Pipa Kapiler Stainless Steel

| ||||

| ITEM | sasmita | Ukuran | dawa | Tekanan (Mpa) |

| 1 | 316L 304L 304 625 825 2205 2507 | 1/8″ × 0,025″ | 3200 | 80

|

| 2 | 316L 304L 304 625 825 2205 2507 | 1/8″ × 0,035″ | 3200 | 100

|

| 3 | 316L 304L 304 625 825 2205 2507 | 1/4″ × 0,035″ | 2000 | 100

|

| 4 | 316L 304L 304 625 825 2205 2507 | 1/4″ × 0,049″ | 2000 | 100

|

| 5 | 316L 304L 304 625 825 2205 2507 | 3/8″ × 0,035″ | 1500 | 80

|

| 6 | 316L 304L 304 625 825 2205 2507 | 3/8″ × 0,049″ | 1500 | 100

|

| 7 | 316L 304L 304 625 825 2205 2507 | 1/2″ × 0,049″ | 1000 | 80

|

| 8 | 316L 304L 304 625 825 2205 2507 | 1/2″ × 0,065″ | 1000 | 100

|

| 9 | 316L 304L 304 625 825 2205 2507 | φ3mm × 0.7mm | 3200 | 80

|

| 10 | 316L 304L 304 625 825 2205 2507 | φ3mm × 0.9mm | 3200 | 100

|

| 11 | 316L 304L 304 625 825 2205 2507 | φ4mm × 0.9mm | 3000 | 100

|

| 12 | 316L 304L 304 625 825 2205 2507 | φ4mm × 1.1mm | 3000 | 100

|

| 13 | 316L 304L 304 625 825 2205 2507 | φ6mm × 0.9mm | 2000 | 100

|

| 14 | 316L 304L 304 625 825 2205 2507 | φ6mm × 1.1mm | 2000 | 100

|

| 15 | 316L 304L 304 625 825 2205 2507 | φ8mm × 1mm | 1800 | 80

|

| 16 | 316L 304L 304 625 825 2205 2507 | φ8mm × 1.2mm | 1800 | 100

|

| 17 | 316L 304L 304 625 825 2205 2507 | φ10mm × 1mm | 1500 | 70

|

| 18 | 316L 304L 304 625 825 2205 2507 | φ10mm × 1.2mm | 1500 | 70

|

| 19 | 316L 304L 304 625 825 2205 2507 | φ10mm × 2mm | 500 | 100

|

| 20 | 316L 304L 304 625 825 2205 2507 | φ12mm × 1.5mm | 500 | 80 |

| Jeneng produk | Stainless Steel Coiled Tubing, Stainless Steel Coiled tabung/pipa, Seamless pipa kapiler, Rolled tubing/pipa, Stainless Steel presisi pipa, Stainless Steel Continuous Oil pipa, Panas sumur Minyak pipa lentur panjang | ||

| Bahan | 304,316L, Duplex 2205, Monel 400, Inconel 825, Inconel 625, UNS N04400, UNS S32205/S31803(ASTM A240), S2507/UNS S32750, API Spec.5ST CT70-CT110, Spesifikasi API.5LCP X52C~X90C | ||

| kekandelan | 0,1-7,62 mm | ||

| OD | 0,3-88,9 mm | ||

| Lumahing Rampung | Annealed lan Padhang,Resik ing njero lan njaba, ora ana burr, lancar loro-lorone. | ||

| Standar | ASTM A269, A213, ASTM A789, ASTM B704, ASTM A370, ASTM A450, APIRP5 C7, JISG4305, JIS G3463, DIN2469, JIS G4305 / GB / T 1272GB /-2000, Spec. Spec.5 LCP | ||

| dawa | Saben muter 200-10000m, utawa minangka saben request klien | ||

| Aplikasi | Platform Pengeboran Minyak, Sumur Minyak, Heatwell.Uga digunakake kanthi akeh ing panganan lenga lan gas, industri panganan, peralatan minuman, mesin bir, penukar panas, sistem pasokan susu / banyu, peralatan medis, energi surya, peralatan medis, penerbangan, aeroangkasa, komunikasi, minyak bumi lan industri liyane, | ||

| Packing | Film gelembung, drum baja, palet baja utawa kothak kayu.Miturut panjalukmu | ||