304 stainless steel roll plate digunakake digunakake ing construction, surgery, kabutuhan pawon, etc.

Deskripsi Produk:

Kumparan baja tahan karatdigunakake digunakake ing construction, surgery, pawon penting, etc. 304 stainless steel cocok kanggo construction saka banisters external lan handrails, lan wis kinerja Processing apik lan weldability.316 stainless steel cocok kanggo pawon penting kayata peralatan, cutlery lan cookware, lan wis resistance karat apik lan sawetara saka sudhut manéka warna.Baja tahan karat 316L cocok kanggo aplikasi medis lan bedah, sing mbutuhake kinerja sing bisa dipercaya.

| Jeneng produk | Stainless Steel Coil/Strip | |

| Teknologi | Dingin digulung, Panas digulung | |

| sasmita | 200/300/400/900 Seri.lsp | |

| Baja tahan karat Austenitik | 200 Seri: 201, 202 | |

| 300 Seri: 304, 304L, 309S, 310S, 316, 316L, 316Ti, 317L, 321, 347 | ||

| Baja tahan karat feritik | 409L, 430, 436, 439, 441, 444, 446 | |

| Baja tahan karat martensit | 410, 410S, 416, 420J1, 420J2, 431,440,17-4PH | |

| Duplex lan Stainless Khusus: | S31803, S32205, S32750, 630, 904L | |

| Standar | ISO, JIS, ASTM, AS, EN, GB, DIN, JIS dll | |

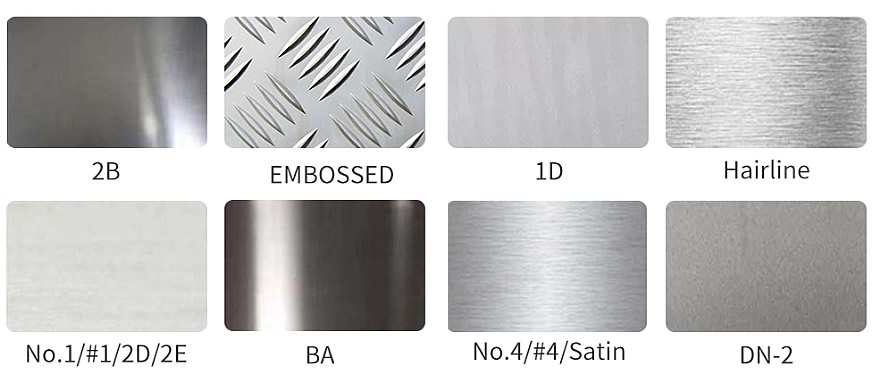

| lumahing | N0.1, N0.4, 2D, 2B, HL, BA, 6K, 8K, lsp | |

| wektu pangiriman | 3-15 dina tundhuk requirement lan jumlahe klien ' | |

| Paket | requirement klien lan Standard ekspor segara-pantes packing | |

| MOQ | 1 ton | |

Kasedhiya Rentang Ukuran

| ukuran | Range |

| kekandelan | Cold Rolled: 0.1 ~ 6mm Hot Rolled: 3 ~ 12mm |

| Jembar | Dingin Role: 50 ~ 1500mm Hot Rolled: 20 ~ 2000mm utawa request customer |

| dawa | Coil utawa minangka request customer |

lumahing umum

Sifat-sifat kimia sing kerep digunakake:

| UNS | ASTM | EN | JIS | C% | Mn% | P% | S% | Si% | Cr% | Ni% | Mo% |

| S20100 | 201 | 1.4372 | SUS201 | ≤0.15 | 5.5-7.5 | ≤0,06 | ≤0.03 | ≤1.00 | 16.0-18.0 | 3.5-5.5 | - |

| S20200 | 202 | 1.4373 | SUS202 | ≤0.15 | 7.5-10.0 | ≤0,06 | ≤0.03 | ≤1.00 | 17.0-19.0 | 4.0-6.0 | - |

| S30100 | 301 | 1.4319 | SUS301 | ≤0.15 | ≤2.00 | ≤0,045 | ≤0.03 | ≤1.00 | 16.0-18.0 | 6.0-8.0 | - |

| S30400 | 304 | 1.4301 | SUS304 | ≤0,08 | ≤2.00 | ≤0,045 | ≤0.03 | ≤0,75 | 18.0-20.0 | 8.0-10.5 | - |

| S30403 | 304L | 1.4306 | SUS304L | ≤0.03 | ≤2.00 | ≤0,045 | ≤0.03 | ≤0,75 | 18.0-20.0 | 8.0-12.0 | - |

| S30908 | 309S | 1.4833 | SUS309S | ≤0,08 | ≤2.00 | ≤0,045 | ≤0.03 | ≤0,75 | 22.0-24.0 | 12.0-15.0 | - |

| S31008 | 310S | 1.4845 | SUS310S | ≤0,08 | ≤2.00 | ≤0,045 | ≤0.03 | ≤1,50 | 24.0-26.0 | 19.0-22.0 | - |

| S31600 | 316 | 1.4401 | SUS316 | ≤0,08 | ≤2.00 | ≤0,045 | ≤0.03 | ≤0,75 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 |

| S31603 | 316L | 1.4404 | SUS316L | ≤0.03 | ≤2.00 | ≤0,045 | ≤0.03 | ≤0,75 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 |

| S31703 | 317L | 1.4438 | SUS317L | ≤0.03 | ≤2.00 | ≤0,045 | ≤0.03 | ≤0,75 | 18.0-20.0 | 11.0-15.0 | 3.0-4.0 |

| S32100 | 321 | 1.4541 | SUS321 | ≤0,08 | ≤2.00 | ≤0,045 | ≤0.03 | ≤0,75 | 17.0-19.0 | 9.0-12.0 | - |

| S34700 | 347 | 1.455 | SUS347 | ≤0,08 | ≤2.00 | ≤0,045 | ≤0.03 | ≤0,75 | 17.0-19.0 | 9.0-13.0 | - |

| S40500 | 405 | 1.4002 | SUS405 | ≤0,08 | ≤1.00 | ≤0.04 | ≤0.03 | ≤1.00 | 11.5-14.5 | ≤0.60 | - |

| S40900 | 409 | 1.4512 | SUS409 | ≤0,08 | ≤1.00 | ≤0,045 | ≤0.03 | ≤1.00 | 10.5-11.75 | ≤0,50 | - |

| S43000 | 430 | 1.4016 | SUS430 | ≤0.12 | ≤1.00 | ≤0,040 | ≤0.03 | ≤0,75 | 16.0-18.0 | ≤0.60 | - |

| S43400 | 434 | 1.4113 | SUS434 | ≤0.12 | ≤1.00 | ≤0,040 | ≤0.03 | ≤1.00 | 16.0-18.0 | - | - |

| S44400 | 444 | 1.4521 | SUS444L | ≤0,025 | ≤1.00 | ≤0,045 | ≤0.03 | ≤1.00 | 17.5-19.5 | ≤1.00 | - |

| S40300 | 403 | - | SUS403 | ≤0.15 | 5.5-7.5 | ≤0.04 | ≤0.03 | ≤0,50 | 11.5-13.0 | ≤0.60 | - |

| S410000 | 410 | 1.40006 | SUS410 | ≤0.15 | ≤1.00 | ≤0,035 | ≤0.03 | ≤1.00 | 11.5-13.5 | ≤0.60 | ≤1.00 |

| S42000 | 420 | 1.4021 | SUS420J1 | 0.16~0.25 | ≤1.00 | ≤0.04 | ≤0.03 | ≤1.00 | 12.0-14.0 | ≤0,75 | ≤1.00 |

| S440A | 440A | 1.4028 | SUS440A | 0.60~0.75 | ≤1.00 | ≤0.04 | ≤0.03 | ≤1.00 | 16.0-18.0 | - | ≤0,75 |

| S32750 | SAD2507 | 1.441 | ≤0.03 | ≤1.2 | ≤0,035 | ≤0.02 | ≤0,80 | 24.0-26.0 | 6.0-8.0 | 3.0-5.0 | |

| S31803 | SAF2205 | 1.4462 | ≤0.03 | ≤2.0 | ≤0.03 | ≤0.02 | ≤1.00 | 21.0-23.0 | 4.0-6.5 | 2.5-3.5 | |

| N08904 | 904L | 1.4539 | ≤0.0.3 | ≤2.0 | ≤0,035 | ≤0.03 | ≤1.00 | 18.0-20.0 | 23.0-25.0 | 3.0-4.0 |

Sifat Bahan Stainless Steel:

| Tipe No. | Kekuwatan tarik, ksi | Kekuwatan Ngasilake, ksi | Elongation ing 2 inci,% | Pengurangan Area,% | Kekerasan Brinell |

| 301 | 110 | 40 | 60 | 70 | 165 |

| 302 | 90 | 40 | 55 | 70 | 150 |

| 303 | 90 | 35 | 50 | 55 | 160 |

| 304 | 85 | 35 | 55 | 70 | 150 |

| 304L | 80 | 30 | 55 | 70 | 140 |

| 316 | 85 | 35 | 60 | 70 | 150 |

| 316L | 78 | 30 | 55 | 65 | 145 |

| 321 | 85 | 35 | 55 | 65 | 150 |

| 410 | 75 | 40 | 35 | 70 | 155 |

| 416 | 75 | 40 | 30 | 65 | 155 |

| 420 | 95 | 50 | 25 | - | 241 |

| 430F | 80 | 45 | 25 | 50 | 165 |

| 15-5 | 160 | 145 | 15 | - | 330 |

| 17-4 (Kahanan A) | 150 | 110 | 10 | 45 | 332 |

Foto produk:

Tulis pesen ing kene lan kirim menyang kita