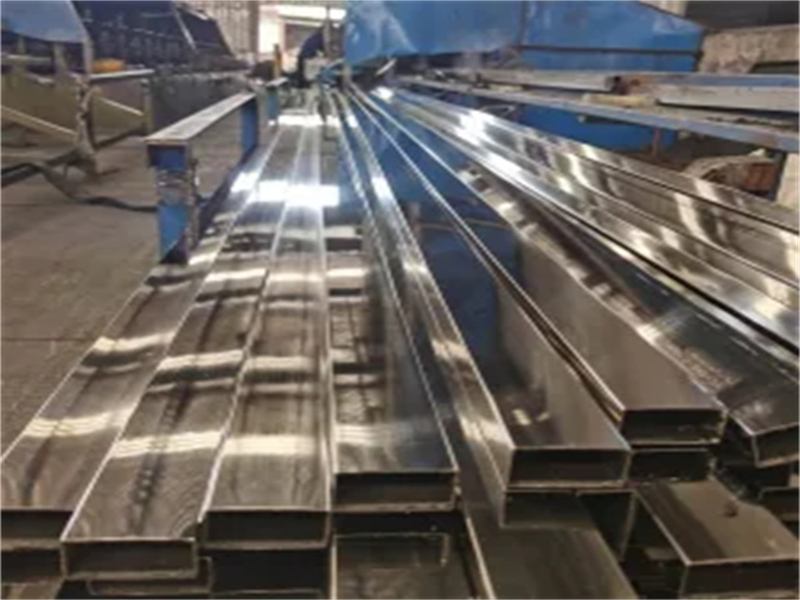

Produsen Pipa Stainless Steel 321 Coil Tube

Spesifikasi:

Produsen Pipa Stainless Steel 321 Coil Tube

1).Diameter: 3.175-50.8mm (1/8"-2inc)

2).Ketebalan: 0.3-3mm

3).Biji: 304 316304 304L 316 316L 310S 2205 2507 625 825 lsp.

4).Standar: GB/ISO/EN/ASTM/JIS, etc.

7. Toleransi: OD: +/-0.01mm;Kekandelan: +/- 0,01%.

8. Lumahing: Padhang utawa anneald lan alus

9. Material: 304, 304L, 316L, 321, 301, 201, 202, 409, 430, 410, alloy 625 825 2205 2507 etc.

10. Packing: LCL kasus kayu poly bay, FCL baja poto utawa poly bay

11. Test: kekuatan ngasilaken, kekuatan tarik, pangukuran hydrapress

12. Jaminan: Pihak katelu (contone: SGS TV) cetification ect.

13. Aplikasi: Dekorasi, Furnitur, nggawe railing, nggawe kertas, mobil, pangolahan pangan, medical.

14: Kauntungan: kita minangka produsen. kanthi kualitas apik lan rega sing cukup. kita bisa ketemu sampeyan kabeh sing dibutuhake.

Kabeh Komposisi Kimia lan Sifat Fisik kanggo Stainless Steel minangka mili:

| Bahan | ASTM A269 Komposisi Kimia % Maks | ||||||||||

| C | Mn | P | S | Si | Cr | Ni | Mo | NB | Nb | Ti | |

| TP304 | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 18.0-20.0 | 8.0-11.0 | ^ | ^ | ^ . | ^ |

| TP304L | 0.035 | 2.00 | 0.045 | 0.030 | 1.00 | 18.0-20.0 | 8.0-12.0 | ^ | ^ | ^ | ^ |

| TP316 | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 16.0-18.0 | 10.0-14.0 | 2.00-3.00 | ^ | ^ | ^ |

| TP316L | 0.035 D | 2.00 | 0.045 | 0.030 | 1.00 | 16.0-18.0 | 10.0-15.0 | 2.00-3.00 | ^ | ^ | ^ |

| TP321 | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 17.0-19.0 | 9.0-12.0 | ^ | ^ | ^ | 5C -0.70 |

| TP347 | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 17.0-19.0 | 9.0-12.0 | 10C -1.10 | ^ | ||

| Bahan | perawatan panas | Suhu F (C) Min. | Kekerasan | |

| Brinell | Rockwell | |||

| TP304 | Solusi | 1900 (1040) | 192HBW/200HV | 90HRB |

| TP304L | Solusi | 1900 (1040) | 192HBW/200HV | 90HRB |

| TP316 | Solusi | 1900(1040) | 192HBW/200HV | 90HRB |

| TP316L | Solusi | 1900(1040) | 192HBW/200HV | 90HRB |

| TP321 | Solusi | 1900(1040) F | 192HBW/200HV | 90HRB |

| TP347 | Solusi | 1900(1040) | 192HBW/200HV | 90HRB |

| OD, inch | Toleransi OD inci (mm) | Toleransi WT% | Toleransi dawa inci (mm) | |

| + | - | |||

| ≤ 1/2 | ± 0,005 ( 0,13 ) | ± 15 | 1 / 8 ( 3.2 ) | 0 |

| > 1/2 ~ 1 1/2 | ± 0,005(0,13) | ± 10 | 1 / 8 (3.2) | 0 |

| > 1 1 / 2 ~< 3 1 / 2 | ± 0,010 (0,25) | ± 10 | 3 / 16 (4.8) | 0 |

| > 3 1 / 2 ~< 5 1 / 2 | ± 0,015 (0,38) | ± 10 | 3 / 16 (4.8) | 0 |

| > 5 1 / 2 ~< 8 | ± 0,030(0,76) | ± 10 | 3 / 16 (4.8) | 0 |

| 8~< 12 | ± 0,040(1,01) | ± 10 | 3 / 16 (4.8) | 0 |

| 12~< 14 | ± 0,050(1,26) | ± 10 | 3 / 16 (4.8) | 0 |